The process of charging and discharging lead-acid batte […]

The process of charging and discharging lead-acid batteries is an electrochemical reaction process. When charging, lead sulfate forms lead oxide, and when discharging, lead oxide is reduced to lead sulfate.

The process of charging and discharging lead-acid batteries is an electrochemical reaction process. When charging, lead sulfate forms lead oxide, and when discharging, lead oxide is reduced to lead sulfate. Lead sulfate is a very easy to crystallize substance. When the concentration of lead sulfate in the electrolytic solution in the battery is too high or the static idle time is too long, it will "hold" into a group and form small crystals, and these small crystals will attract the surrounding The lead sulfate forms large inert crystals like snowballs. When the crystallized lead sulfate is charged, not only can it not be reduced to lead oxide, but also precipitate and adhere to the electrode plate, causing the working area of the electrode plate to decrease. This phenomenon is called Vulcanization, also known as aging. At this time, the battery capacity will gradually decrease until it can no longer be used.

work environment factors

As long as it is a lead-acid battery, it will be vulcanized during use, but lead-acid batteries in other fields have a longer life than those used in electric bicycles. This is because the lead-acid batteries of electric bicycles have an easier vulcanization. work environment.

1. Deep discharge

The lead-acid battery used in the car only discharges in one direction during ignition. After ignition, the generator will automatically charge the battery without causing deep discharge of the battery. Electric bicycles cannot be charged when riding, and often exceed 60% of the deep discharge. During deep discharge, the concentration of lead sulfate increases, and the vulcanization will be quite serious.

2. High current discharge

The 20-kilometer cruising current of an electric vehicle is generally 4A, which is already higher than the working current of batteries in other fields, and the working current of an over-speed and overloaded electric vehicle is even greater. Battery manufacturers have conducted cycle life tests of 70% charge at 1C and 60% discharge at 2C. After such a life test, there are many batteries that can reach a lifespan of 350 charge-discharge cycles, but the actual effect is far from the same. This is because high current operation increases the depth of discharge by 50%, and the battery will accelerate vulcanization. Therefore, the battery life of the electric three-wheeled motorcycle is shorter, because the body of the three-wheeled motorcycle is too heavy, and the working current is more than 6A.

3. High frequency of charge and discharge

The battery used in the field of backup power supply will only be discharged when the power is cut off. If the power is stopped 8 times a year, to achieve a life of 10 years, it only needs to achieve 80 cycles of charging life, while electric vehicles charge and discharge cycles 300 times a year. Times and above are common.

4. Short charge

Since the electric bicycle is a means of transportation, there is not much time for charging. It needs to be charged at 20A at 36V or 48V within 8 hours. This requires increasing the charging voltage (usually 2.7~2.9V for a single cell). When charging When the voltage exceeds the oxygen evolution voltage (2.35 volts) or the hydrogen evolution voltage (2.42 volts) of a single cell, the battery will open the valve and exhaust due to excessive oxygen evolution, causing water loss, increasing the electrolyte concentration, and increasing the vulcanization of the battery. .

5. Can not be charged in time after discharge

As a means of transportation, the charging and discharging of electric bicycles are separated, and it is difficult to charge in time after discharge. If a large amount of lead sulfate formed after discharge is not charged and reduced to lead oxide for more than half an hour, it will vulcanize and form crystals.

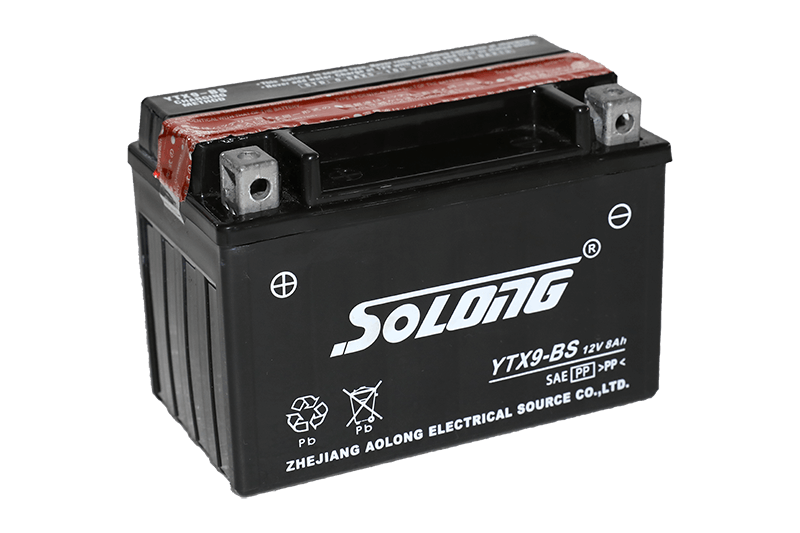

Founded in 2004, Zhejiang Aolong Electrical Source Co., Ltd. is VRLA Battery Manufacturers and Sealed Lead Acid Battery Factory. The company occupied a land area of more than 70000 square meters, with more than 700 employees, the annual output of lead acid battery can reach to 10 million pcs. As a high-end professional company which with more than 40 years of professional manufacturing and management experiences, A collection of independent research and development, production, sales and service as one of the high-end professional lead-acid battery business enterprises, the main production and management products include motorcycle battery, e-bike battery, automotive battery, vrla sealed battery five series of hundreds of lead-acid batteries. The company offer wholesale VRLA Sealed Lead Acid Battery for sale, has passed the management system and product certification of ISO9001, ISO14001, GB/T28001,CE, UL, etc. We looking forward to cooperate with more customers at home and abroad, and work together to create brilliant!